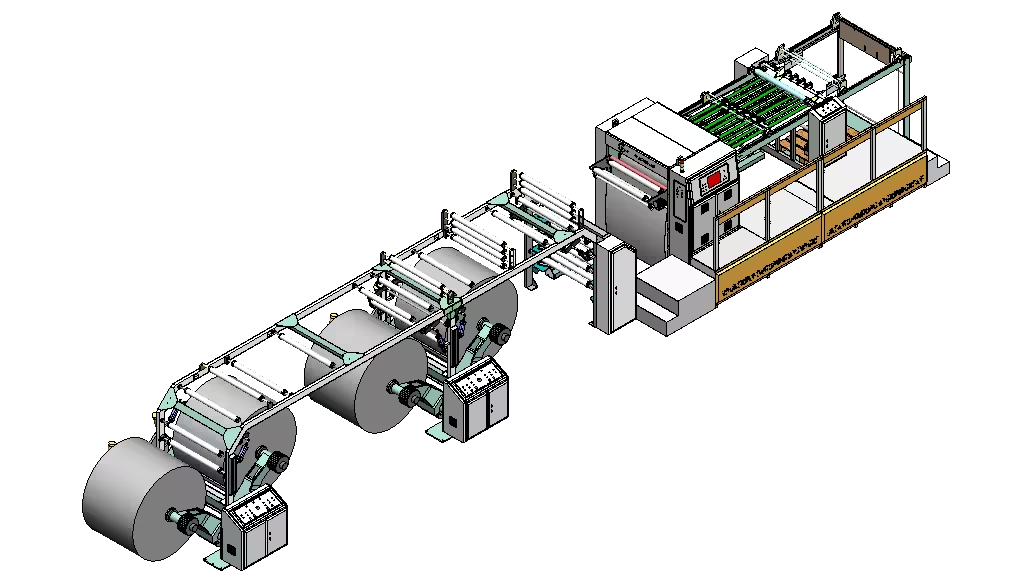

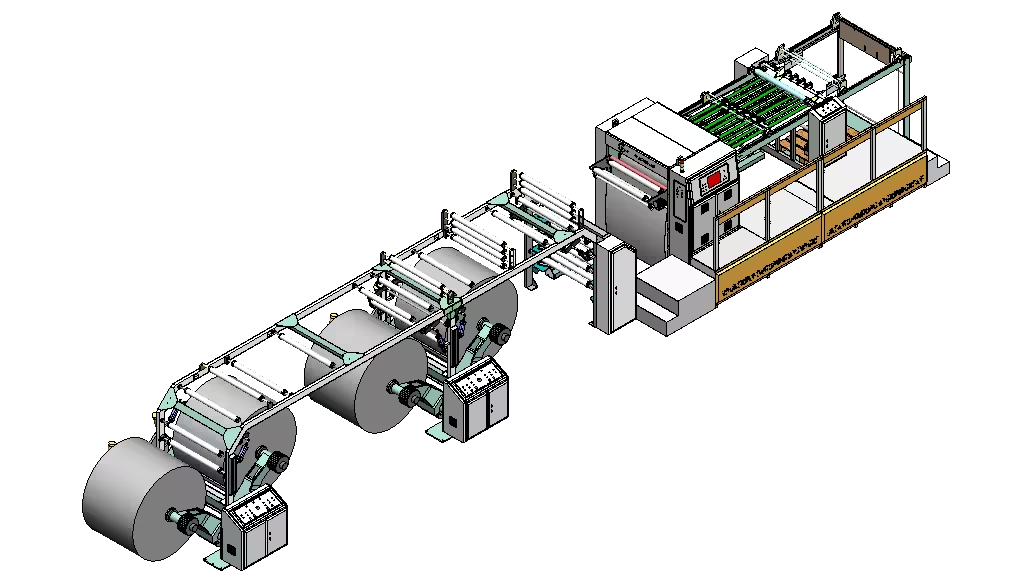

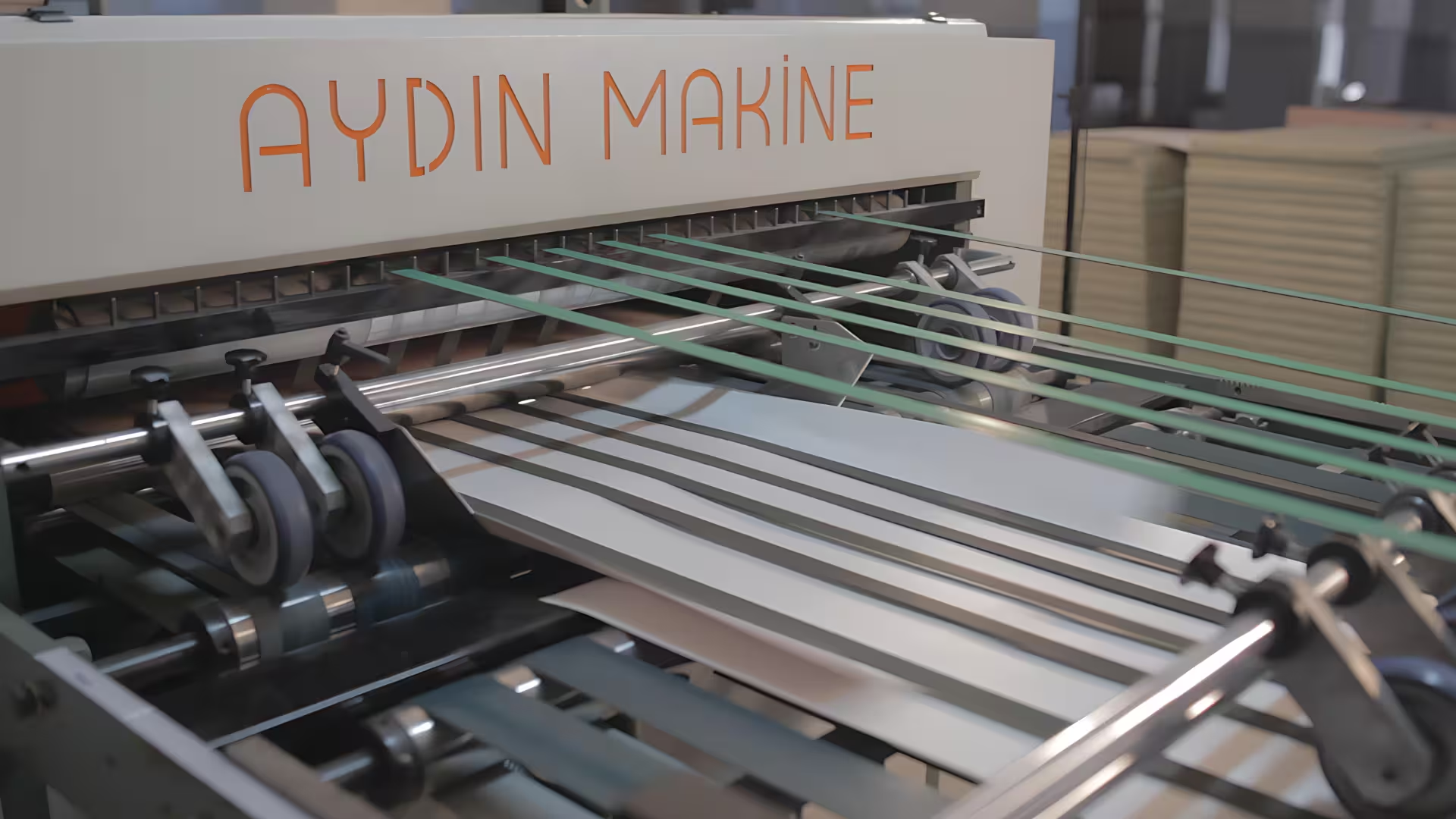

Paper Sheeter Machine Image Gallery

Paper Sheeter MachineFour Rolls

- High Speed

- Precision Cutting

- Smart Automation

Industries Served

Printing Industry

Ideal for sheet-fed printing presses, where precise paper sizes are essential for high-quality prints.

Packaging Industry

Used to cut paper, cardboard, or other materials into specific sizes for packaging boxes or protective wraps.

Paper Converting

Ideal for paper converters who require precise cutting of paper into specific dimensions for subsequent processing or production stages.

Speed

300 m/min.

Cutting Precision

± 0.25 mm

Multilingual Touchscreen Display

EN DE TR RU

Automatic Hydraulic Shaftless Unwind Stand

The unwind stand is equipped with an advanced hydraulic lifting system that ensures smooth and easy roll lifting and loading. The hydraulic mechanism offers precise control over roll positioning, minimizing manual labor.

Pneumatic Air-Cooled Brakes

It uses compressed air to activate and deactivate the braking system in synchronization with the automatic tensioning system, regulating the pressure for smooth deceleration. The air-cooled design prevents overheating during prolonged use, ensuring consistent performance and long lifespan.

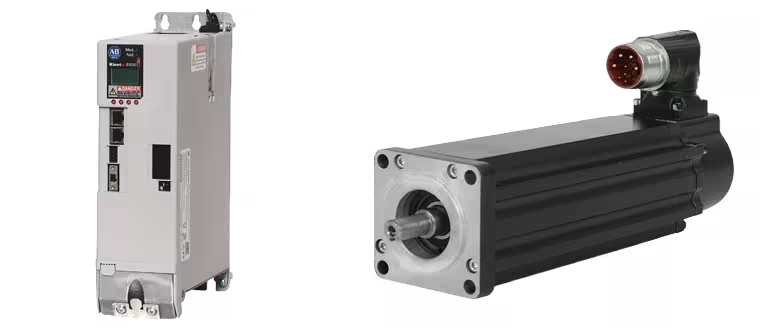

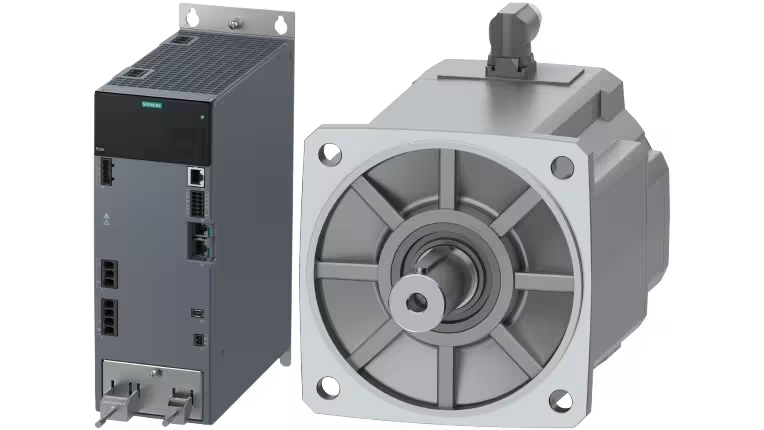

Twin Servo Drives and Twin Servo Motors

Equipped with twin servo drives and twin servo motors to ensure maximum precision, synchronization, and high-speed operation across all critical components of the paper sheeting process.

Automatic Tension Control

Our Automatic Tension Control system works seamlessly with the brake system to maintain consistent tension during the paper sheeting process. This ensures precise cutting, reduces waste, and boosts productivity by improving overall efficiency and quality in each operation.

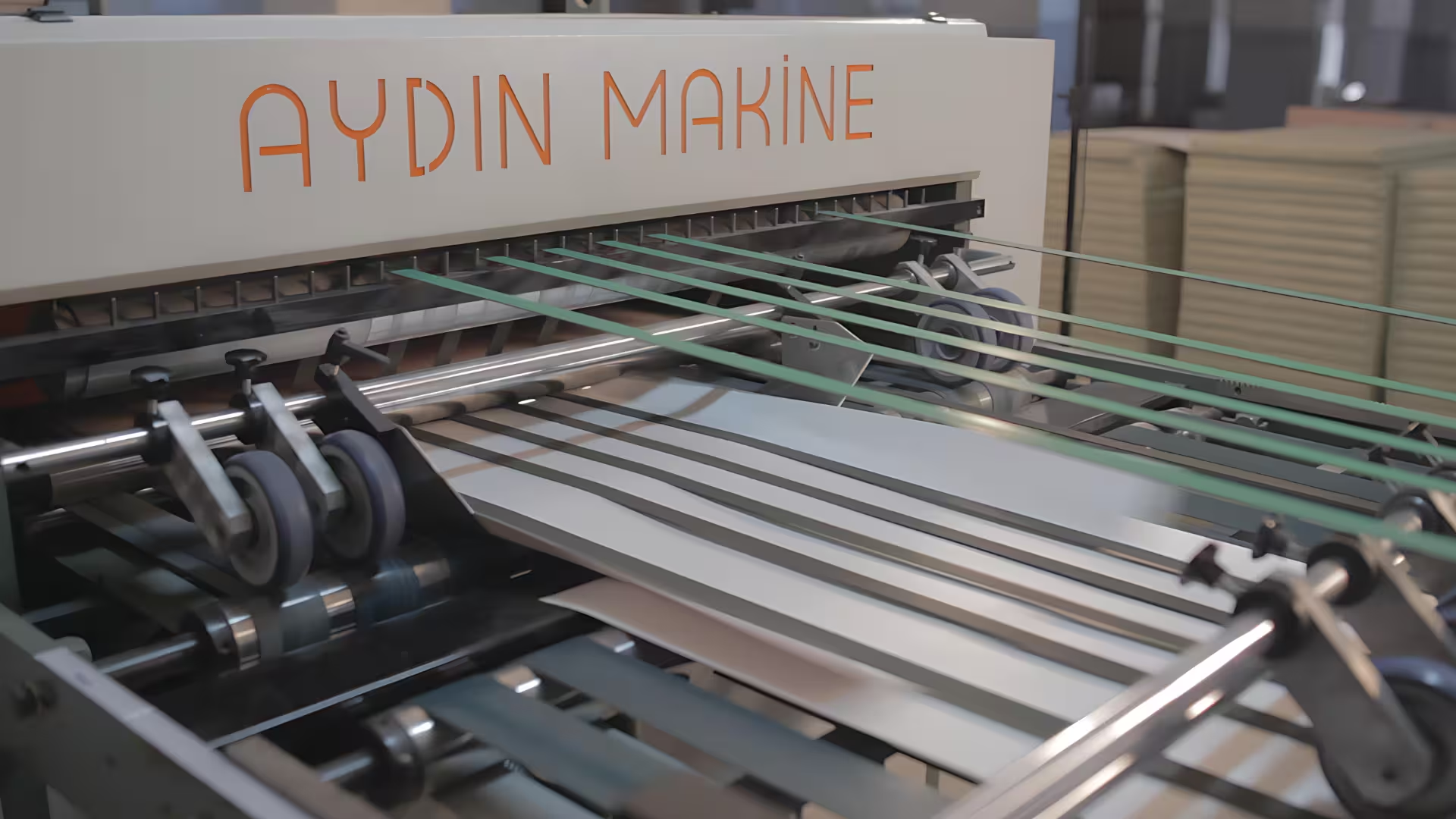

Pneumatic Pulling Roller

The pneumatic roller, which can be moved up and down, covered with rubber, ensures easy placement of the paper into the machine. The pressure applied by the roller to pull the paper is controlled through pressure adjustment, ensuring the same tension across the entire printing surface. This prevents tearing and achieves optimal traction.

Paper and Cardboard Decurling Unit

A decurling unit in a paper sheeter machine refers to a mechanism that removes the natural curl or curl tension that paper tends to develop after being produced on a paper machine. This is important to ensure the paper feeds smoothly and accurately into the sheeter for cutting into sheets of the desired size.

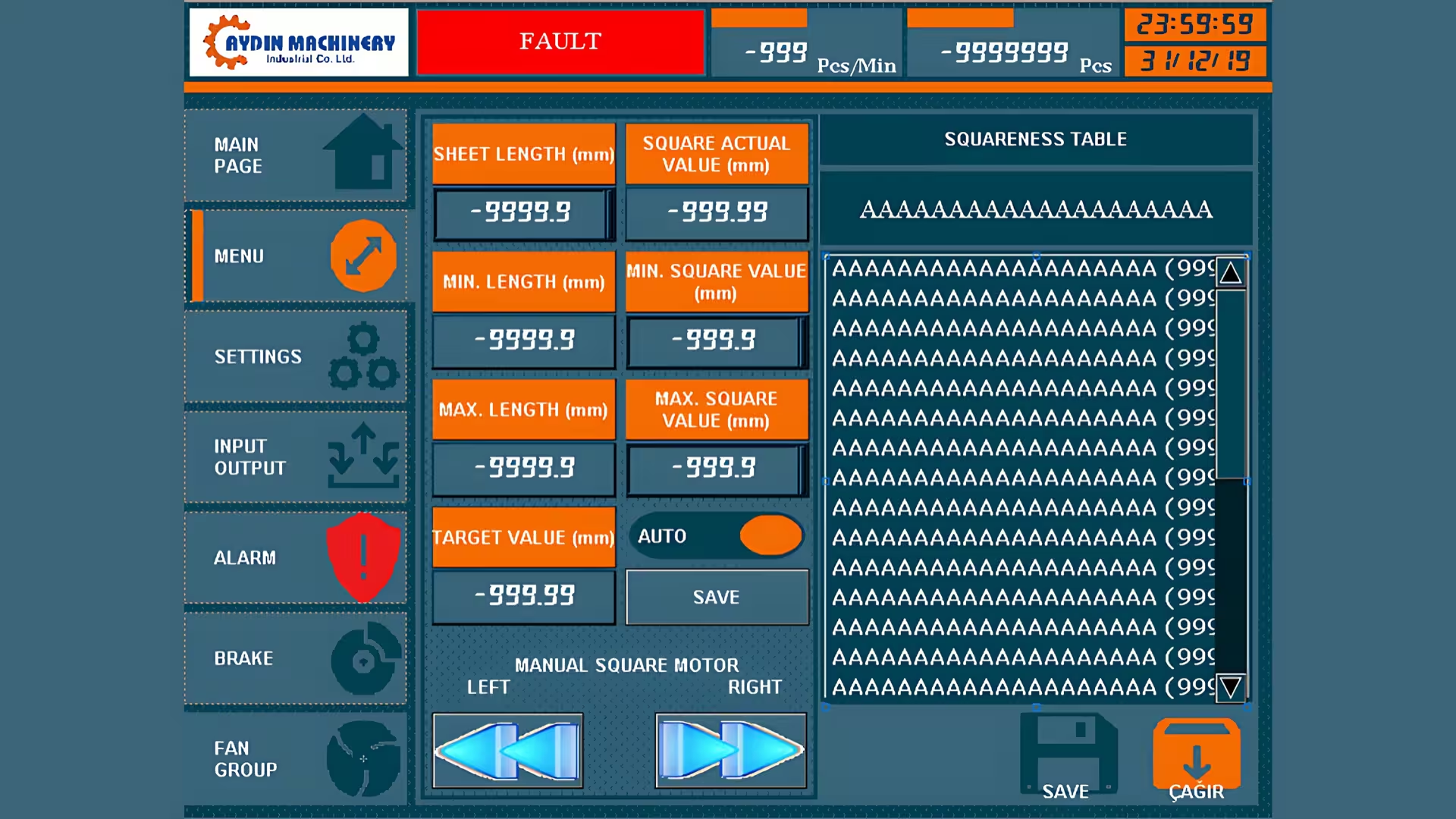

User-friendly Computerized Motion Control with Touchscreen Control Panel

Optimize your paper sheeting with our automatic squaring system, which adjusts automatically when the sheet length changes. This advanced system ensures precise alignment, reduces waste, and perfectly squared corners, all while maintaining accurate dimensions for various sheet sizes.

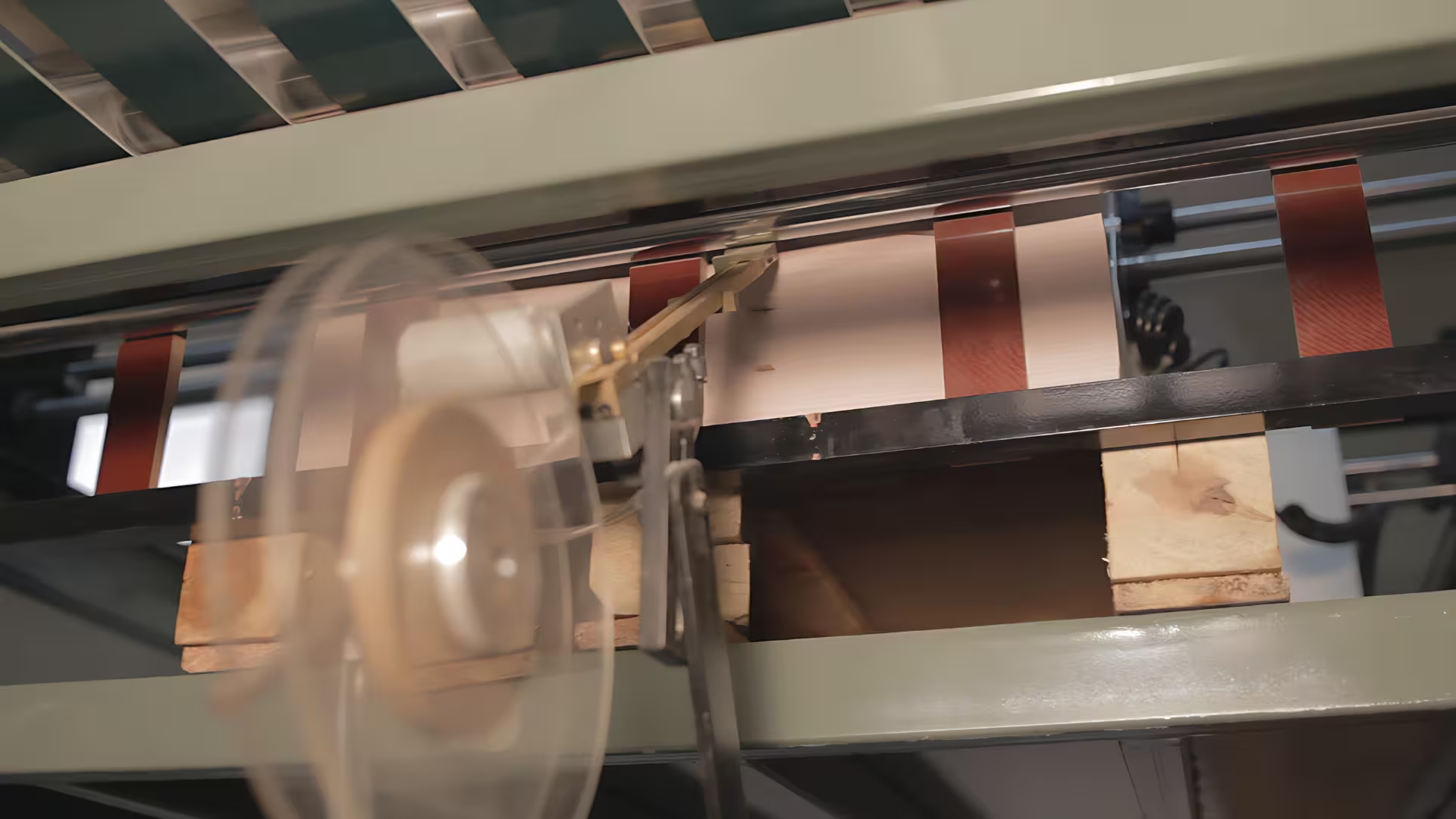

Automatic Squaring System

Achieve precise cuts with consistent accuracy, ensuring every sheet has perfectly squared corners. This innovative solution guarantees optimal alignment and quality, reducing waste and improving efficiency in your paper cutting processes. Enhance production and streamline operations effortlessly.

Adjustable Stacker Unit and Band Conveyor Unit

It is equipped with an adjustable stacking unit and a belt conveyor system for efficient paper collection operations. The stacking unit can be easily adjusted for different paper sizes, while the belt conveyor system ensures smooth and consistent transfer, enhancing workflow and productivity.

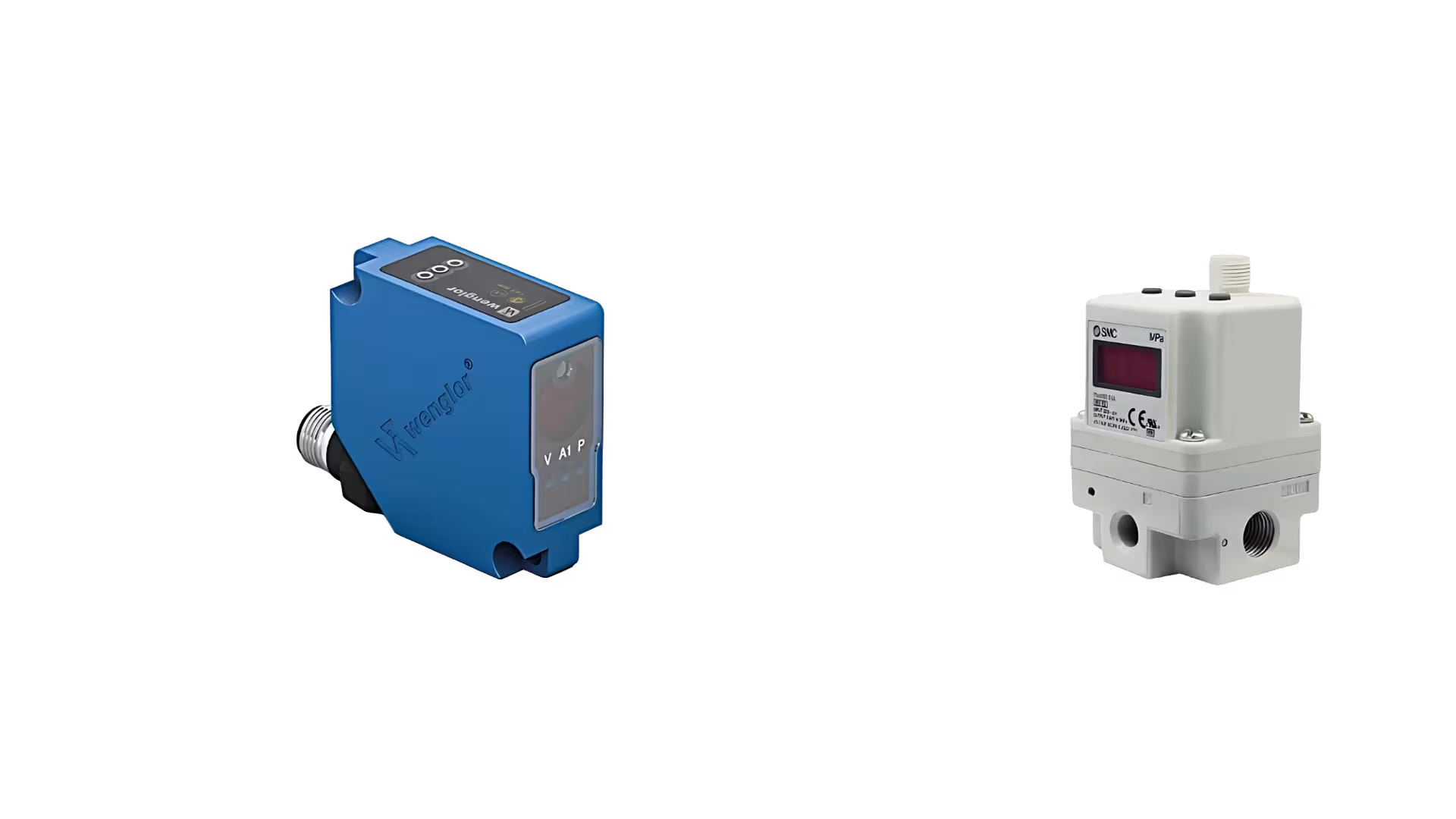

Sheet Counting Sensor and Sheet Stacking with Vibration

It accurately counts the sheets and efficiently stacks them. The system automatically moves the lift up and down according to the sheet stack using a photocell. Proper collection is ensured with vibration motors on each sides.

Cones [Core Chucks]

It offers superior performance with various sizes ranging from 3" to 12". The cones, equipped for a large surface area and efficient torque transfer, minimize damage to the cardboard cores and open crushed cardboard cores smoothly.

![Cones [core chucks]](/images/products/paper-sheeter-machines/core-chuck.avif)

Options

Technical Specifications

- Technical Specifications

Models

Roll Dimensions

Roll Width[max.]1050 mmRoll Width[min.]300 mmRoll Diameter[max.]Ø1600 mmØ2000 mm [optional]Roll Density[min.]40 gsm [g/m²]Roll Density[max.]500 gsm [g/m²]Roll Weight[max.]3000 kgSheet Dimensions

Sheet Length[max.]1500 mmSheet Length[min.]400 mmStack Dimensions

Pile Height[max.]1400 mm[incl. pallet]Size and Weight

Model:1100Length11 mWidth3 mHeight2.4 mWeight8.5 t